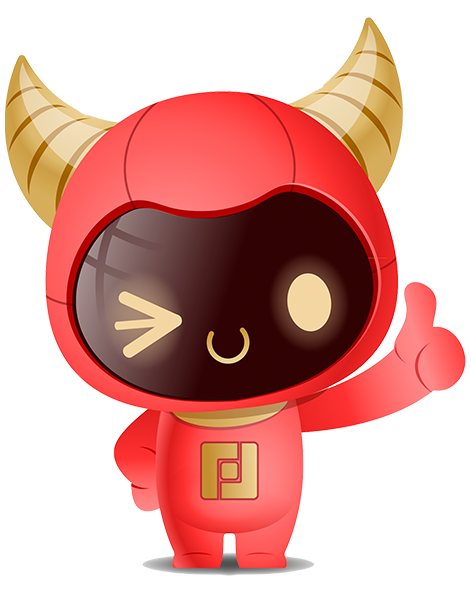

Engine transport rack (capable of loading six sets)

Category:

Product Description

Product design concept

The engine transport rack is an auxiliary equipment designed for the transportation, storage and installation of the engine. It uses high-strength materials and advanced design concepts to ensure the safety, stability and convenience of the engine during transportation. The transport rack is suitable for various types of engines, such as automobile engines, marine engines, industrial engines, etc., and is an indispensable tool for engine manufacturers, logistics, transportation and maintenance industries. The product has been carefully designed with strong load-bearing capacity and stable structure, which can effectively prevent the engine from shifting or damaging during transportation. At the same time, we pay attention to the safety of products and adopt anti-skid and anti-collision designs to ensure the safety of the engine during transportation. In addition, the transport rack is simple to operate, which is convenient for workers to load and unload quickly and improve work efficiency.

Product specification parameters

| Name | Engine transport rack (capable of loading six sets) |

| Appearance size | 2150*1300*820mm (customizable) |

| Body Material | Q235 carbon steel |

| Surface treatment | spraying baking varnish |

| Body Color | Blue/Green/Grey |

| form of production | Welding |

| Authorized Bearing | 1500kg |

| Stackable | 5 floors |

| Self-weight | 200kg |

| Packing size | 2150*1300*2600mm |

| Loading volume | 6.8 meters truck, 35 units |

Production process

1. Made of high-quality steel or other high-strength materials, with good compression and bending resistance. At the same time, the surface of the transportation frame is specially treated to have anti-corrosion, anti-rust and wear resistance;

2. Automatic high-precision cutting equipment for cutting; welding adopts automatic welding robot imported from Japan, and there is no manual welding in the whole process. High welding efficiency, strong strength, beautiful weld;

3. Automatic spraying line one-time spraying, high efficiency and high quality;

4, assembly line operation, efficient and high quality to complete the assembly. We also carry out strict quality inspection and testing on the transport rack to ensure that the products meet the relevant standards and requirements.

Product use

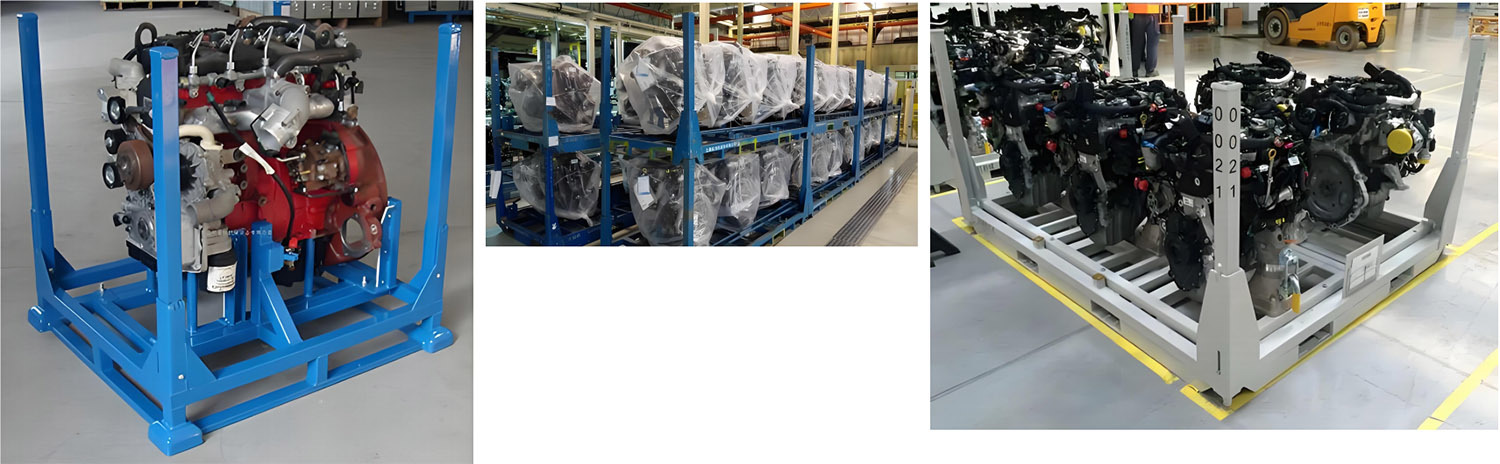

1. Engine manufacturing: used for transportation and storage of engine production lines.

2. Logistics transportation industry: In the process of logistics transportation, it is used for engine loading, unloading and transportation.

3. Automobile maintenance industry: In the process of automobile maintenance, it is used for engine disassembly, transportation and installation.

Related cases

Product Expansion

Core Advantages

Scale Advantage

The operating area of the enterprise is 10000 square meters, and the production workshop covers an area of 7000 square meters;

8 Panasonic robots and 2 large CNC laser machines;

10 punching machines, 2 continuous punching machines, and 8 CNC shearing and bending machines;

1 spraying assembly line and 1 pipe making machine assembly line;

Annual production of 100000 sets of material handling equipment.

Quality Advantage

Production strictly complies with ISO9001:2015 quality system and BSI quality management system;

High end automated production equipment robots, helping to improve quality;

Strictly control dimensional tolerances to meet the gripping needs of robotic arms;

The processing and spraying of steel pipes are entirely carried out by our own factories to ensure quality;

Full process inspection from raw materials to finished products.

Technical Advantages

Having multiple invention patents, utility model patents, and design patents;

4 people with over 15 years of industry technical experience, 6 experienced designers, and 3 senior engineers;

Provide design drawings based on the storage capacity/utilization rate of the material rack, supporting logistics supply chain, and product load-bearing capacity;

Use advanced genuine drawing software for 3D modeling and simulation.

Service Advantages

Samples will be produced within 15 days, and bulk delivery will begin within 25 days;

The transportation of goods shall be strictly packaged according to requirements and delivered to the doorstep;

The warranty period for non-human damage to the product is 1 year;

The material rack is foldable/stackable, reusable, and has a normal service life of about 5-8 years.