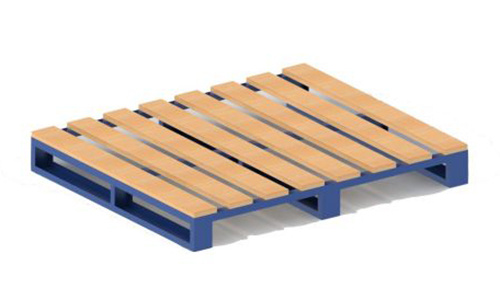

Iron steel tray

Category:

Product Description

Product design concept

Simple design concept, with flexible and changeable combination mode. Meet your needs in different application scenarios.

|

|

|

|

| Anti-collision corner protector | Bending C- Plate | Foot | Connecting piece |

Product specification parameters

| Name | Iron steel tray |

| Appearance size | 1000*800*150mm/1200*1000*150mm |

| Body Material | Q235 carbon steel |

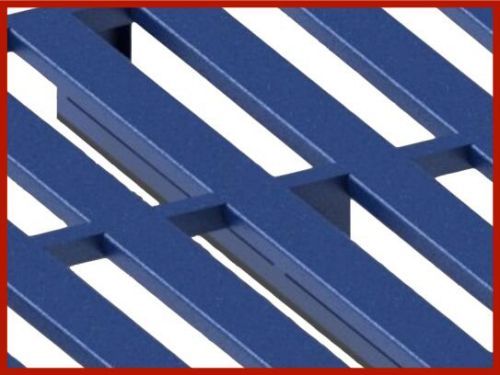

| Surface treatment | spraying baking varnish |

| Body Color | Blue |

| form of production | Welding |

| Authorized Bearing | 1000-1500kg |

Production process

1. high quality cold-rolled pipe is adopted;

2, automatic high precision cutting equipment to cut off;

3. The welding adopts automatic welding robot imported from Japan, and there is no manual welding in the whole process. High welding efficiency, strong strength, beautiful weld;

4. Automatic spraying line one-time spraying, high efficiency and high quality

5, assembly line operation, efficient and high quality to complete the assembly.

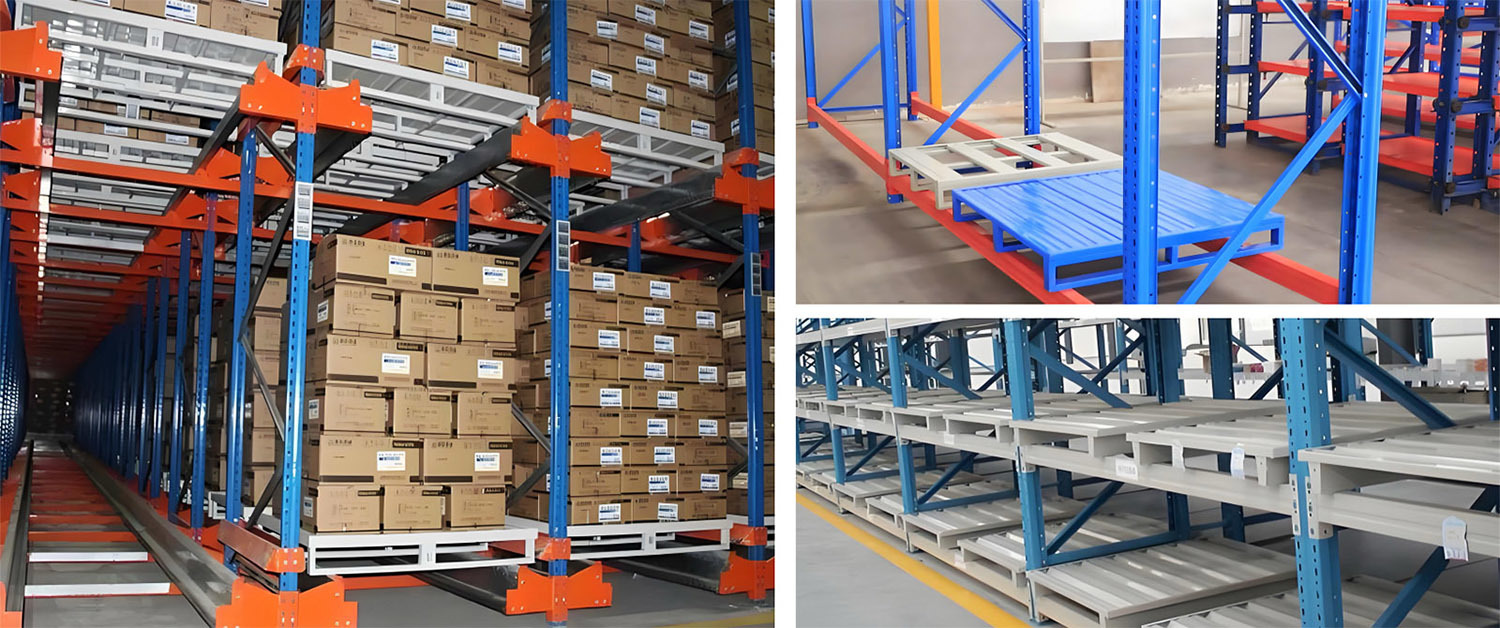

Product use

Stacking, storage and transportation of various items.

Product expansion

|

|

|

|

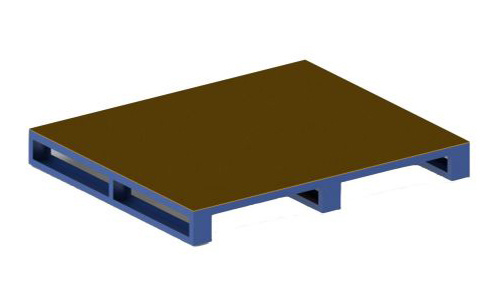

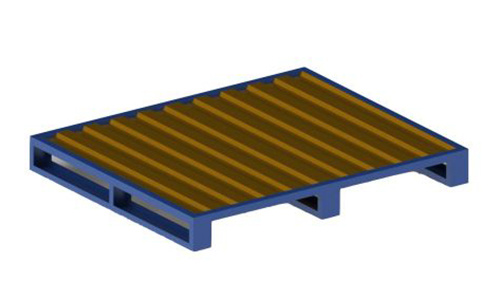

| Iron spacer panel type | Wood Spacer Panel Type | Iron plane plate type | Iron wave panel type |

Related cases

Product Expansion

Core Advantages

Scale Advantage

The operating area of the enterprise is 10000 square meters, and the production workshop covers an area of 7000 square meters;

8 Panasonic robots and 2 large CNC laser machines;

10 punching machines, 2 continuous punching machines, and 8 CNC shearing and bending machines;

1 spraying assembly line and 1 pipe making machine assembly line;

Annual production of 100000 sets of material handling equipment.

Quality Advantage

Production strictly complies with ISO9001:2015 quality system and BSI quality management system;

High end automated production equipment robots, helping to improve quality;

Strictly control dimensional tolerances to meet the gripping needs of robotic arms;

The processing and spraying of steel pipes are entirely carried out by our own factories to ensure quality;

Full process inspection from raw materials to finished products.

Technical Advantages

Having multiple invention patents, utility model patents, and design patents;

4 people with over 15 years of industry technical experience, 6 experienced designers, and 3 senior engineers;

Provide design drawings based on the storage capacity/utilization rate of the material rack, supporting logistics supply chain, and product load-bearing capacity;

Use advanced genuine drawing software for 3D modeling and simulation.

Service Advantages

Samples will be produced within 15 days, and bulk delivery will begin within 25 days;

The transportation of goods shall be strictly packaged according to requirements and delivered to the doorstep;

The warranty period for non-human damage to the product is 1 year;

The material rack is foldable/stackable, reusable, and has a normal service life of about 5-8 years.